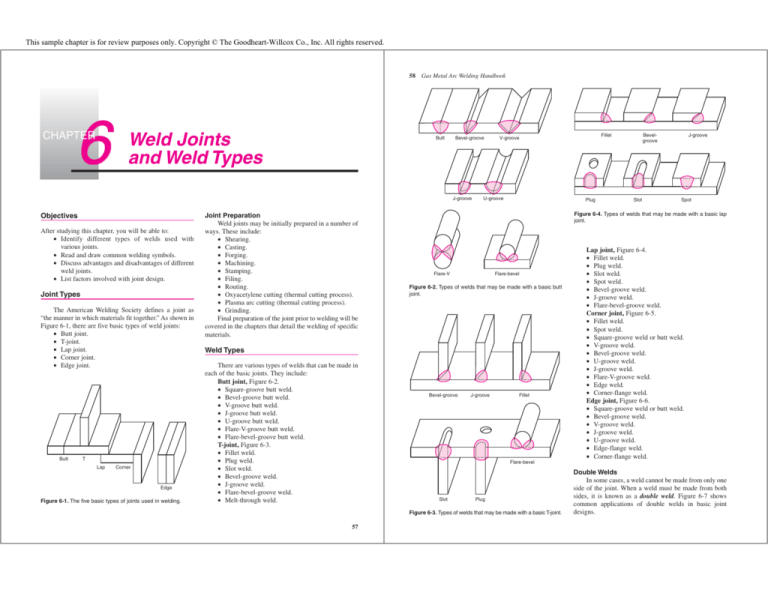

Variations such as grooving the welded metal and using an open corner joint instead of a closed corner joint. Basic Types of Welds.

Types Of Welds And Welding Symbols Welding Productdesign Design Designengineering Mechanical Types Of Welding Engineering Memes Engineering Design

11822 12122 Drawings are due on Friday Jan.

. Advancing rapidly from basic concepts and processes to todays most complex cutting-edge welding technologies and practices this comprehensive text features valuable information on topics such as welding metallurgy metal fabrication weld testing and inspection joint design job costing and environmental and conservation tips. The bracket material is. If a total of 10 allowances are allowed for this operation.

Chapter 18 Activity. Your assignment this week is to draw out welds on plates using 6010 and 7018 rods in different positions. Principles and Applications features more tight shots of actual welds to speed beginners to an understanding of a variety of different welding processes used today.

Locate and apply required weld and joint information from an AWS welding symbol. Types of welding defects associated with the corner joint are lamellar tearing incomplete penetration porosity slag inclusion etc. Welding Joint Design Welding Symbols and Fabrication Chapter 18.

Take advantage of that tape. Learn vocabulary terms and more with flashcards games and other study tools. Be creative and detailed on your drawings.

There are three basic types of welds. This is accomplished in a standardized and abbreviated picture format which makes easily used in every country around the world. This chapter describes the fundamentals of weld joint design including the parameters that are obtained after designing a weld joint.

Log in Sign up. Up to 24 cash back Welding Process Major effect on selection of joint design Each welding process has characteristics that affect its performance Some processes are easily used in any position Others may be restricted to one or more positions Rate of travel penetration deposition rate and heat input also affect welds. A T joint is a joint where two metal plates are at a 90 degree angle and one of the pieces connects away from the edge.

Paint a strip of tape blue using a nail polish. For the ultimate step use a nail artwork glue to adhere the bow in your nail. This is a preview of subscription content log in to check access.

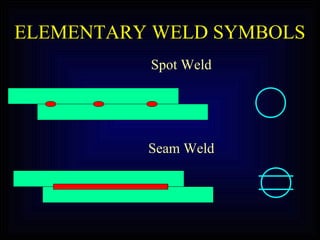

S ut 400MPa S y 220MPa 1 Factor of safety guarding against static yielding in. A lap joint is where one plate lays on top of another plate. Welding symbols graphically convey complete information about a weld or braze joint.

Available in full-color the fifth edition of Welding. Chapter 1- The Welding Inspector 6 Terms. ButtThis is a joint where two plates are butted together edge to edge.

Up to 10 cash back Abstract. Start studying Welding Joint Design and Welding Symbols. Plastic and Other Nonmetallic Fabrication Techniques Appendix Bilingual Glossary Index.

This groundbreaking new text offers a complete hands-on guide to professional welding and fabrication from print reading through invoicing via small material-conserving projects that hone essential welding skills while allowing students to be creative making exercises both practical and personaland avoiding the tedium of traditional repetitive welding practices. Remaining chapters in the section zero in on individual welding tasks and must-know techniques. The complete symbol system is described in ANSIAWS A24 Standard Symbols for Welding Brazing and Nondestructive Testing latest edition.

Welding symbols and their components are created using the same units the drawing in which they are displayed. Welding Principles and Applications Fifth Edition Larry Jeffus Australia Canada Mexico Singapore Spain United Kingdom United States. Modes of failure rigidity and stiffness loading condition welding symbol type of weld and weld joint 221 Introduction Weld joints may be subjected to variety of loads ranging from a simple tensile.

The welded joint will occur at the edge of the top plate. Experiments allow readers to develop new hands-on skills while gaining an understanding of the parameters of each welding process discussed in the book. American Welding Society- CWI Welding Inspection Technology Chapter Examination 2008 146 Terms.

Metal welding is the process of joining metallic materials by applying heat andor pressure with or without the addition of a corresponding material of the same or approximately the same melting temperature or traject. CHAPTER 3 DESIGN CONCEPT AND SELECTION 30 Introduction 16 31 Design 16 32 Drawing 16 33 Concept Selection 17 331 Concept 1 332 Concept 2 333 Concept 3 17 18 19 34 Evaluation Table and Concept Discussion 20 35 Final Design 21 36 Conclusion 21 CHAPTER 4 FABRICATION PROCESS 40 Introduction 22 41 Material Of The Project 22. Welding Joint Design and Welding Symbols.

Features more tight shots of actual welds to speed beginners to an understanding of a variety of different welding processes used today. F x 5340cos30 46246N F y 5340sin30 2670 N M 534000095 5073Nm From Table A-20. The operator took on an average 8 minutes for producing the weld-joint.

Additionally weld penetration is significantly less. Plug and slot welds Other types of welds include. What is the expected standard production rate of the weld-joint in units per 8 hour day.

Learning Objectives After studying this chapter you will be able to. Similar to tee joints. Welding Joint Design Welding Symbols and Fabrication.

21 2022 at 1159pm. Identify and describe the various welds that may be used in each welding joint. Comprehensive coverage spans from specific welding processes to discussion of related topics including welding metallurgy metal fabrication weld testing and inspection joint design and job costing.

To minimize the occurrence of these defects a little variation can be applied. Just incorporate a small drop to your nail and press the bow on it. Identify the five basic welding joints.

A type of welding that is generally limited to thin materials high-integrity joints or small parts because of its low welding speed and high cost of equipment and materials. Gas Tungsten Arc Welding of Pipe. The joint design should allow for the first weld bead to be deposited with a convex surface.

Moving quickly from basic concepts to the study of todays most complex welding technologies each section begins by introducing readers to the. JS11 Joint Design Welding Symbols Student Handout for. Label the parts or areas of a grooved butt weld and a fillet weld.

Give it a few minutes to dry. Sketch a weld on plates in the 1G and 1F positions. 96 F y produces tension throughout the weld F x produces shear throughout the weld M produces a bending stress in the welds with tension at A and compression at C Therefore.

Moving quickly from basic concepts to the study of todays most complex welding technologies each section begins by introducing readers to the materials equipment setup procedures and critical safety information they need to know to. An included weld angle or root opening that is too narrow promotes the formation of a concave weld bead that places the weld surface in tension and promotes solidification cracking in the weld metal. Chapter 18 welding joint design welding symbols and fabrication.

A welding operation is time-studied during which an operator was pace-rated as 120. Arc spot and seam welds Edge welds Flange welds Surfacing welds Seal welds.

Weld Joints And Weld Types Goodheart

Engineering Drawing And Design Seventh Edition Chapter 18

Welding Joint Design And Welding Symbols Pdf Welding Construction

Engineering Drawing And Design Chapter 18 Welding Drawings Ppt Video Online Download

Chapter 5 Welding Joint Design And Welding Symbols

Engineering Drawing And Design Chapter 18 Welding Drawings Ppt Video Online Download

0 comments

Post a Comment